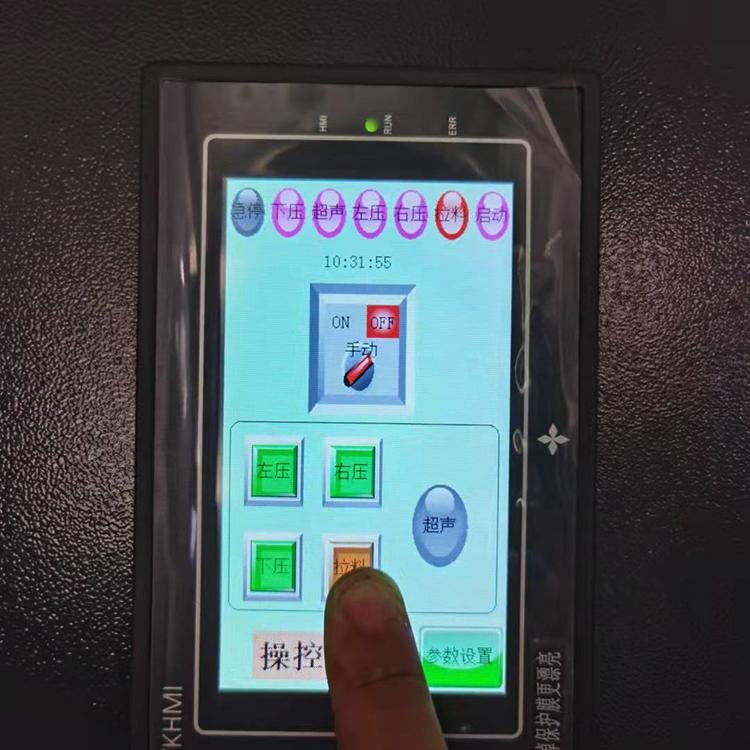

It is used for processing and welding between hanging lath and sheet base in printing industry. It is a semi-automatic equipment, built in combination with industry characteristics, with strong adaptability and simple operation.

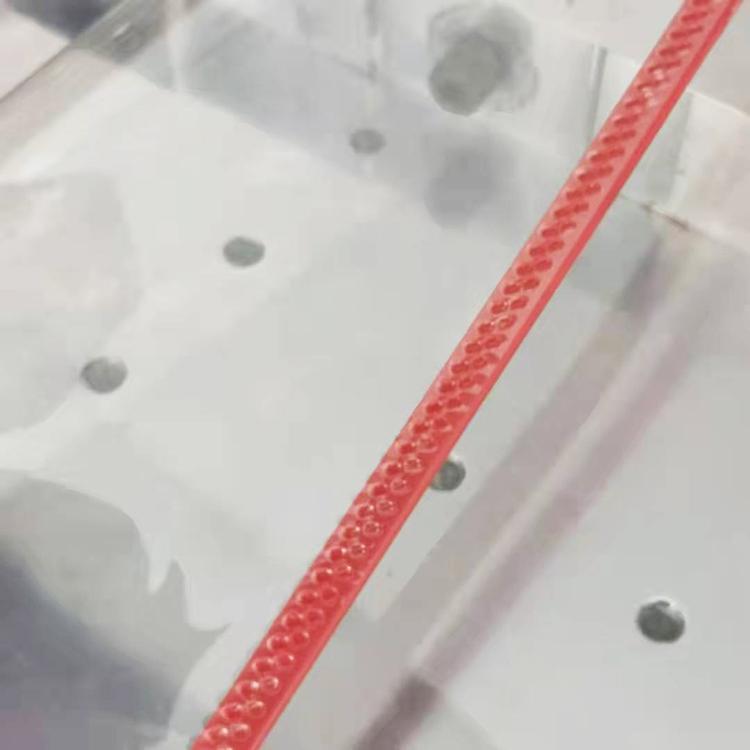

The welding material is batten ABS, with a thickness of 3mm and a width applicable to 7.8 9.10. Four size battens

The film base is made of pet with a thickness of 0.175mm.

Equipment size: 800 * 900 * 1900mm

Equipment weight: 240kg

Equipment power: 2600w frequency: 15KHz

The printing and hanging plate continuous strip base press uses ultrasonic welding technology, The ultrasonic energy is transmitted to the welding area of the plastic part through the upper weldment (upper mold) The acoustic resistance (the interface between the two welding parts) is relatively large, resulting in local high temperature in the welding area. Due to the poor thermal conductivity of the plastic, the heat that cannot be dissipated in time can accumulate in the welding area, resulting in the rapid melting of the contact surface of the two plastic parts, which is integrated under a certain external pressure. After the ultrasonic wave stops working, the continuously applied external pressure solidifies and forms the welding surface Form a solid molecular chain to achieve the purpose of welding, and its welding strength can be close to the strength of raw materials.

Working characteristics of printing plate hanging strip base press

Fast - each welding time is 0.01-9.99 seconds

Strength ---- can withstand large tension and high pressure

Quality - no water leakage, no air leakage, gas tight welding, no damage to plastic parts during welding

Economy - no screws, glue. Reduce labor and low cost