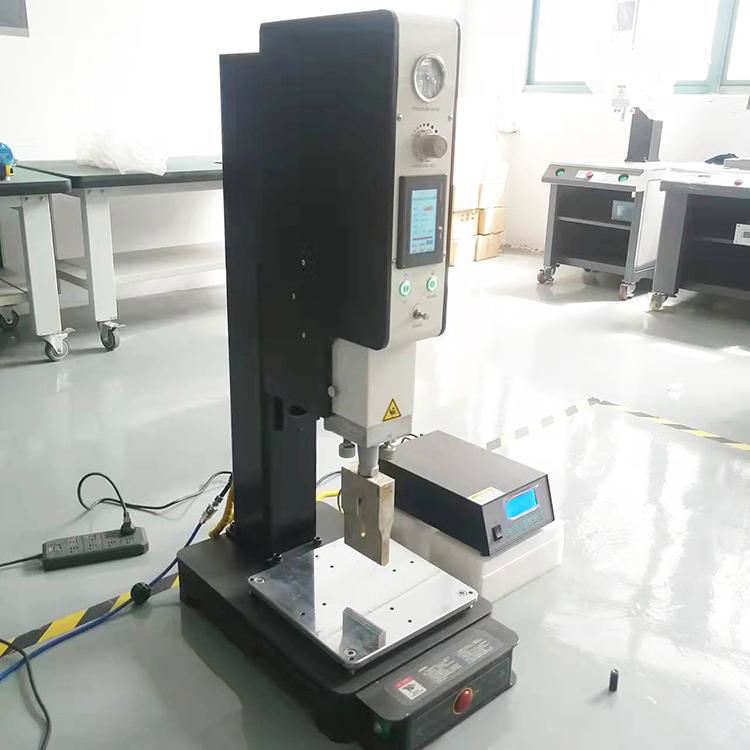

| Model: | ZSVI-WJ-2615 |

|---|---|

| Brand: | zsvi |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Welding Solders |

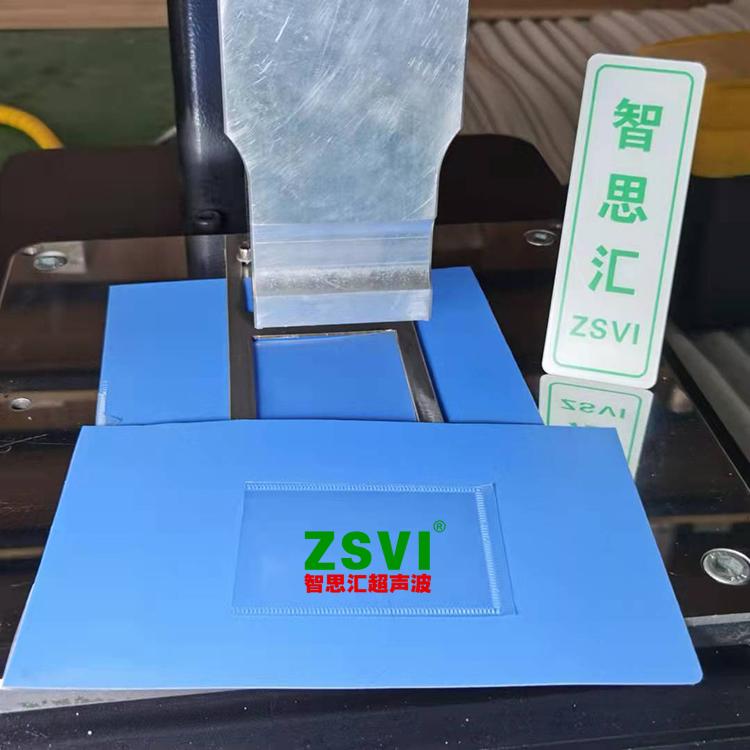

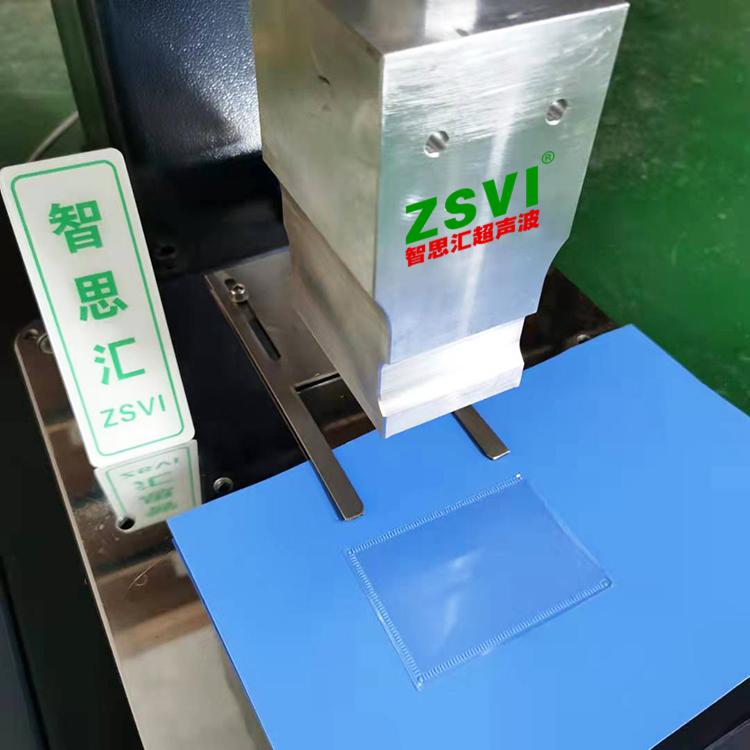

| Label: | filder folder make , plastic machine , ultrasonic welding |

| Price: |

US $1750

/ pc

|

| Min. Order: | 1 pc |

Product Description

Ultrasonic mold is a high-tech technology for welding thermoplastic products. All kinds of plastic parts can be treated by ultrasonic welding without adding adhesive or other auxiliary products. Its advantages are to increase productivity, reduce cost and improve product quality.

Frequency range: 15KHz, 20kHz, 28kHz, 30kHz, 35kHz, 40KHz, 60Hz

Ultrasonic die materials: alloy steel, magnesium aluminum alloy, titanium alloy

Delivery date: three working days

Processing equipment: Lathe CNC lathe milling machine wire cutting spark machine CNC engraving and milling machine

Inspection equipment: three dimensional element, laser amplitude analyzer, impedance analyzer

Scope of application: it is suitable for welding thermoplastic rubber products. All kinds of injection molded rubber parts can be treated by ultrasonic welding without dissolving. Widely used

Member Information

| wuxi zsvi welding technology limted company | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Manufacturer |

| Phone: | 15006191865 |

| Contact: | Lisa (seller manager) |

| Last Online: | 14 Dec, 2021 |

Related Products of this Company

-

ultrasonic welding machine

US $1700

-

liquid filter bag top and bottom

US $4800

-

liquid filter bags ultrasonic welding

-

Ultrasonic generator and transducer

US $1200

-

Digital automatic plastic ultrasonic

US $6000

-

Nylon woven bag wireless ultrasonic

US $750

-

pp hollow plate corrugated sheet box

US $2300

-

Face Masks Anti-Fog with face shield

US $1850

-

Ultrasonic Welding Machine for Car and

US $2000

-

china 4200w ultrasonic welding machine

US $6000