| Model: | XD series |

|---|---|

| Brand: | WINCOO |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Welding Machinery |

| Label: | orbital welding , pipe welding , tube welding |

| Price: |

US $8000

/ pc

|

| Min. Order: | 1 pc |

Product Description

Technical parameter

|

Model |

XD-20W |

|

Duty cycle |

200A 60% /155A 100% |

|

Welding current |

5-200A |

|

Floating voltage |

65V |

|

Input voltage |

AC220V±10% 50Hz/60Hz |

|

Power |

4.5 KVA |

|

Torch cooling |

Built-in circulating water cooling |

|

display |

Ten inch touch screen |

|

Storable program |

99 units |

|

Partition Free Space |

12 units |

|

Insulation grade/protection grade |

F/IP21 |

|

control function |

Dc/pulse current control, gas control, rotary motion, automatic/manual print control, water cooling control |

|

Protective function |

Over voltage, overload, leakage, arc starting failure and tungsten needle short circuit protection, missing item detection |

|

Capacity of tank |

4L |

|

Weight |

33KG(includes cooling water 4L) |

|

Over size |

510mm×353mm×340mm |

Advantages:

- Color 10 inch screen, reasonable graphic design, ergonomic operation habits;

- Siemens PLC control system ensures fast operation, accuracy and reliability of welding process parameters. Low maintenance cost;

- Double cooling system, greatly improve welding torch temporary load rate;

- Years of welding data accumulation, summarizing big data directly call;

- Real-time welding monitoring, graphic interface design, simple and direct;

- Light weight, high altitude operation is simple;

- Welding gun design exclusive patent technology, guarantee welding quality;

- With one-button printing and automatic printing function, built-in mini free maintenance printer;

- Core components imported from Germany ensure the stability of the equipment.

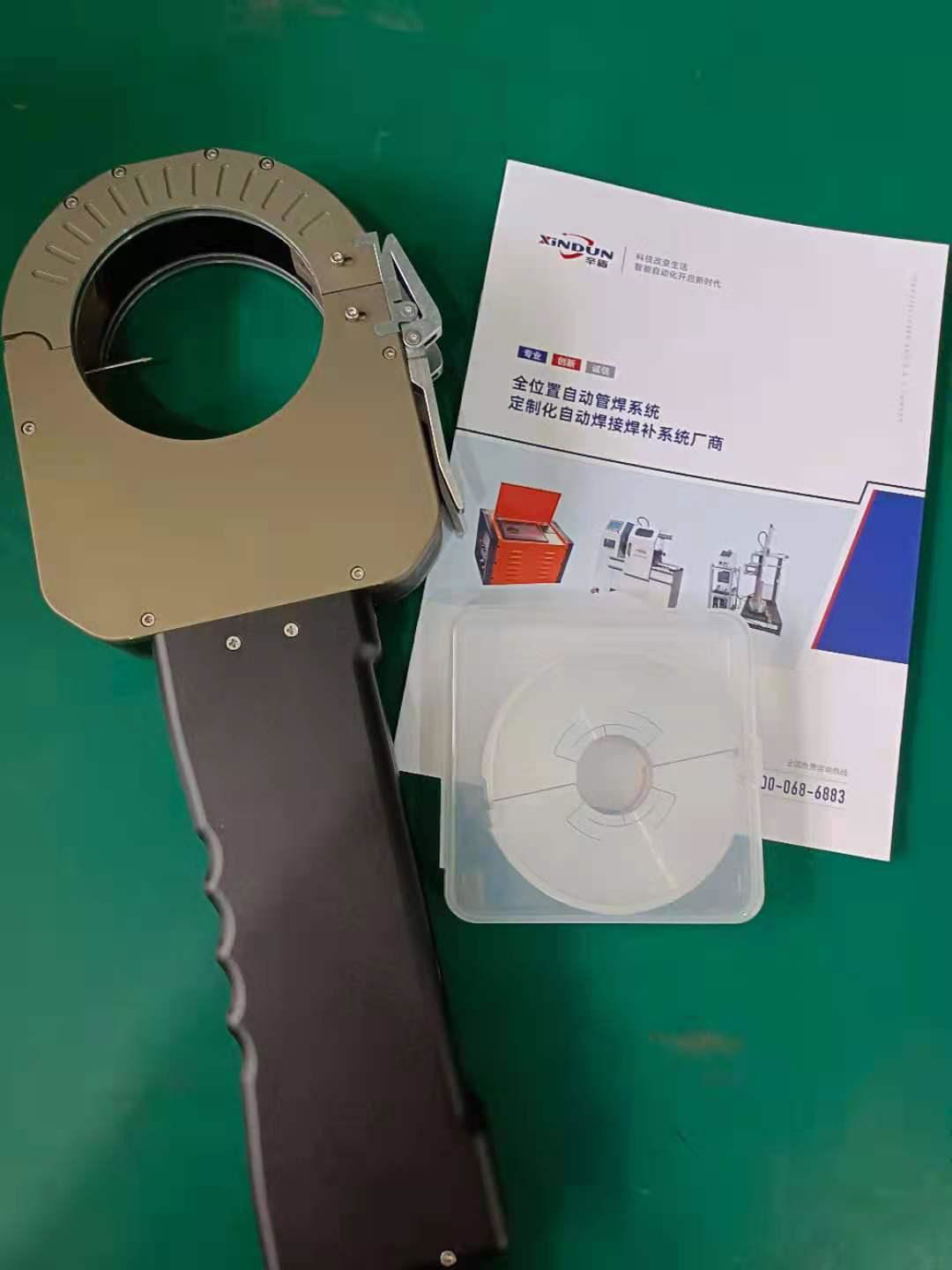

Overview/advantages of closed tube welding torch

Overview:

This welding torch is a special welding torch designed and developed for all position automatic welding of various pipe fittings.

Advantages:

Motor: German Planet motor

The inner wall of the welding torch is water-cooled to improve the temporary load rate of the welding torch.

The torch uses a combination of core imported materials and aluminum barrel for light weight and reliability.

Patented clamps with flexibility reduce pipe fitting requirements.

Special leakage hole shape, effectively ensure the weld beautiful.

Self - locking spring mechanism, easy and firm to change fixture.

Welding torch handle operation keys: forward turn, reverse, emergency stop, attenuation, start, indicator light

Technical parameter

|

Closed type welding torch |

|||

|

Model |

XD40 |

XD80 |

XD120 |

|

Power source |

XD-20W all position power source |

||

|

Material of workpieces |

Carbon steel, stainless steel, titanium alloy, etc |

||

|

Diameter(mm) |

6.35-38.1 |

19.05-76.2 |

38.1-114.3 |

|

Max thickness (mm) |

2.5 |

3 |

|

|

Torch cooling |

Water cooling |

||

|

Rotating speed(rpm) |

0.3~6.0 |

0.2~5.3 |

0.1~3.8 |

|

Protective gas |

Argon |

||

|

Weight (kg) |

3.5 |

5 |

6.5 |

|

Size (mm) |

377x129x42 |

438x155x44 |

540x195x54 |

Process conditions

- Welded pipe diameter: φ 6.35mm- φ 114.3mm

- Pipe thickness: 0.5-3mm

- Tungsten electrode diameter: φ 1.6mm- φ 2.4mm

- Welding clamp rotation speed: 0.15rpm-4.5rpm

- Pipe material: carbon steel, stainless steel, titanium and titanium alloy, etc

- Welding mode: rotating non-winding all-position welding mode, with automatic reset function

- Welding pipe fitting form: straight pipe, tee, elbow, chuck, reducer and other butt, no groove opening, self-fusion welding

- Protective gas: argon

- Cooling water flow: 1000mL /min

- When welding carbon steel tube, welding joint 5-8mm to polish rust, exposed metal primary color

- The tube incision should be flat, vertical and burr free, and there is no gap between the two tubes

- Clean oil stains with acetone or alcohol

- The handle of welding clamp is equipped with operation button, which is convenient for personnel to operate and improve working efficiency

- When welding the pipe mouth, the length of the straight line segment can be held ≥20mm

- Draw a circle with the center of the welded pipe fitting as the center, and there shall be no obstacles within the range of R=80mm

Main configuration suppliers

|

Name |

Brand |

Origin |

|

Power source |

EWM Imported from Germany |

Germany |

Member Information

| WINCOO ENGINEERING LTD.,CO | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Trading Company |

| Phone: | 15366132650 |

| Contact: | Mucyo (sales departments) |

| Last Online: | 12 Jul, 2022 |

Related Products of this Company

-

TIG Pipe Welding Equipment

US $25000

-

Tank welding machine tank construction

US $25000

-

mig 200A gasless welder MIG TIG MMA with

US $86

-

WSME-200 380V 200A TIG Welders TIG and

US $310

-

LGK-50 built-in air compressor plasma

US $290

-

Tank or vessel girth seam and vertical

US $3150

-

Tank welding machine tank construction

US $3200

-

TIG 200 ARC WELDING MACHINE

US $135

-

200A Mini Welding Machine and MMA

US $35

-

PIPELINE WEDLING MACHINE/ORBITAL WELDING

US $3500