| Model: | DY 6T/8T/10T |

|---|---|

| Brand: | DY |

| Origin: | Made In China |

| Category: | Chemicals / Plastic Materials |

| Label: | tire pyrolysis plant , pyrolysis plant , pyrolysis |

| Price: |

US $35000

/ SET

|

| Min. Order: | 1 SET |

| Last Online:24 Jan, 2018 |

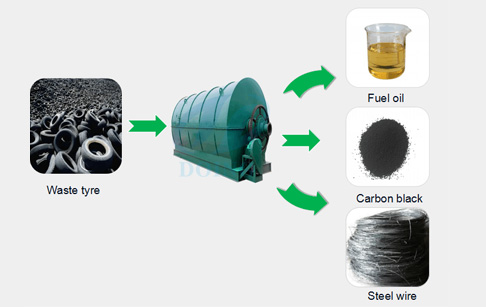

Waste tire pyolysis plant

Cars bring great convenience to our life. At the same time, discarded tires on the car also endangered our living environment. Dongying Group, on the basis of this social problem, developed the technology of waste tire heat Solutions, has become China's largest waste tire pyrolysis plant provider! This technology receives more and more attention, its main principle of work is as follows:

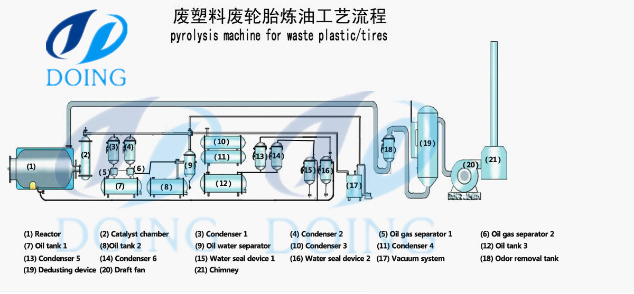

Waste tire pyrolysis plant working process

1. Use mechanical waste tires to enter the reactor and close the inlet to prevent gas flow out.

2. Carbon, wood or fuel heating reactor, the reactor is generally 200-300 degrees is the beginning of the cracking reaction, when the waste tire is vaporized into oil vapor.

3.Oil and gas into the condensing system, liquefied into oil, was collected in the tank device. Our system has a negative pressure device, he can greatly enhance the production of pyrolysis oil.

4, liquefied petroleum gas that can not be liquefied under atmospheric pressure is returned to the reactor as combustion fuel, which is not only energy saving and environmental protection.

5. After the completion of oil production, the reactor will be cooled. When the temperature drops to 40 degrees, the carbon black and wires will be removed automatically or manually.

The reason why waste tire pyrolysis plant can cause widespread concern in society, but also because it has the following advantages:

1. Standard pressure vessel, Q245R standard boiler plate, thickness 16mm.

2. Seamless welding process, not easy to crack, long service life.

3.360 degree omnidirectional insulation cover, thermal insulation effect is more prominent.

4. Negative pressure seal device to ensure safe and efficient operation of equipment. Negative pressure equipment can increase the oil rate.

5. Environmental protection, energy saving. Our tire pyrolysis plant has a special dust removal device, waste liquid can be achieved waste disposal, will not cause any harm to the environment.

The wide range of uses of tire pyrolysi plant final product:

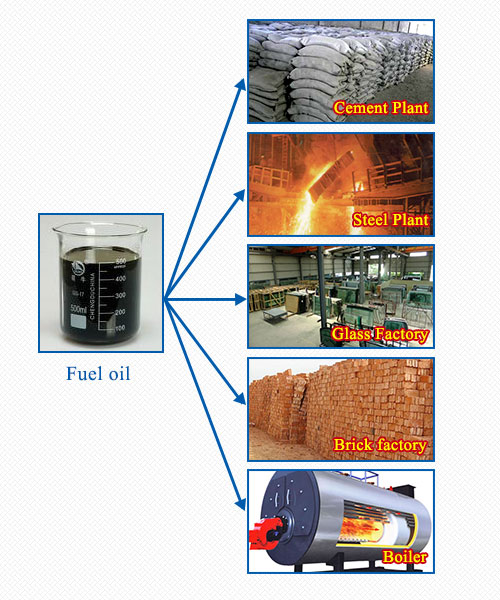

Fuel oil application

1. Fuel oil can be used in steel mills, boiler heating, heavy oil power plants and cement plants to produce refined diesel for further processing and diesel generators, light fuels, heavy machinery.

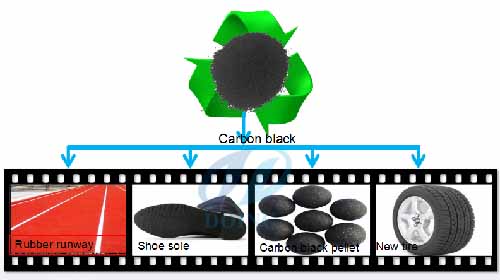

Carbon black application

2. Carbon black can be used for pressure ball burning, refined toner. Can be used for new tires, rubber soles, pigments made of refined toner.

3. Steel wire is mainly used for scrap recycling, and re-cast into other steel.

4. Combustible gas is mainly used for circulating heating reactor.

As a supplier of waste tire pyrolysis plant in China, we will make our contribution to alleviating the world's energy crisis and protecting the ecological environment, and our tire pyrolysis plant will have a broader market prospect. Any questions about the device, please contact us!

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.wastetireoil.com

http://www.china-doing.com