| Model: | DY 6T/8T/10T |

|---|---|

| Brand: | DY |

| Origin: | Made In China |

| Category: | Chemicals / Plastic Materials |

| Label: | plastic pyrolysis , pyrolysis plant , pyrolysis |

| Price: |

US $45000

/ SET

|

| Min. Order: | 1 SET |

| Last Online:24 Jan, 2018 |

Waste plastic pyrolysis plant

Plastic products are widely used, everywhere plastic waste.The recycling of waste plastics has increasingly become an important part of environmental protection. DoingGroup has developed a waste plastic processing equipment in addition to plastic waste. The waste plastic pyrolysis recycal can also handle waste solid waste organic waste such as waste tires / waste rubber / waste acrylic / garbage / medical waste / oil shale, the operation of the device is as follows:

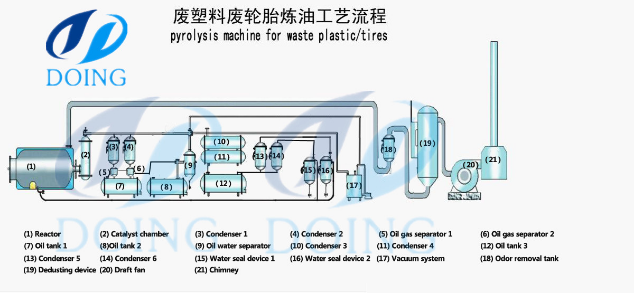

Waste pyrolysis plant working process

1. The waste plastics and other organic solid waste by the conveyor belt to the bunker by the automatic feeding system to the cracking furnace, rotating the main furnace can control the positive and negative reversing switch control switch to adjust the organic raw materials in the main furnace of the material distribution, the total amount of material control in the total volume below two thirds, close the feed sealing door, and then open the heating system.

2. When the temperature reaches about 150 ℃, gas will be generated (most of the gas is the exhaust gas at this time). When the temperature reaches about 220 ℃, oil and gas will start to enter the multi-function separator. After the multi-function separator, there will be some oil separation down, the pipeline into the residual tank, the pump into the cracking furnace to continue heating cracking.

3. Oil and gas into the cooling system through the multi-function separator, the condensed oil and water flows into the oil-water separator through the pipe for oil-water separation measurement. Under the action of negative pressure, the non-condensable gas enters the micro-vacuum system through the cooling system piping and is filtered again.

4. The pyrolyzed flue gas enters the powerful atomization dedusting tower through the flue pipe to spray dust and cool down, and is discharged into the industrial exhaust gas purifier by the induced draft fan, finally reaching innocuous discharge.

Waste plastic pyrolysis recycal is not only able to degrade the plastic waste in life, reduce environmental pollution, but also produce more renewable energy to ease the energy crisis, more and more because of its own advantages as follows:

3. Pinion rotation device, power is small, not directly contact the reactor, less heat transfer, not easy to deformation.

4. The three-stage cooling system uses tube condensation, also known as a heat exchanger, and is currently the most commonly used and best performing condenser in the oil industry. Can ensure that the cracked oil and gas fully cooled, high oil yield.

5. Safety device oil-water separator, water seal, vacuum device, to ensure safe and efficient operation of equipment.

The waste plastic pyrolysis recycal will produce lysis oil, carbon black, combustible gas.

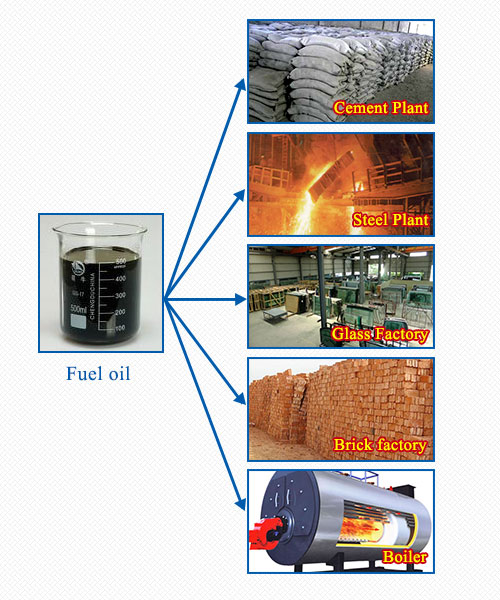

Fuel oil usage

Cracking Oil: Steel Plant, Boiler Heating, Heavy Oil Generator, Cement Plant.

Carbon black usage

Carbon black: pressure ball burning, refining flour. Which refined flour and can be used for new tires, rubber, plastic, paint manufacturing.

Combustible gas: It is recycled by the equipment for combustion heating of the reactor.

Waste plastics and other waste is the simplest way to deal with landfill and simple incineration. Landfills need a lot of valuable land resources. Since the development of waste rubber, waste plastics, fuel oil pyrolysis equipment has become a common research and attention of all levels of government issues. It not only saved valuable land resources for human beings, but also created a new topic of new energy. The waste plastic pyrolysis recycal investment occupies 450 square meters of production space, plant simple, rich source of raw materials, low cost, large profit margins, the recovery of fuel oil is widely used. Running one day there will be tens of thousands of dollars of revenue. Domestic customers can recover all the investment within three months, Southeast Asia investment customers a month and a half to recover all the investment.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.wastetireoil.com

http://www.china-doing.com