| Model: | DY 6T/8T/10T |

|---|---|

| Brand: | DY |

| Origin: | Made In China |

| Category: | Chemicals / Plastic Materials |

| Label: | plastic pyrolysis , pyrolysis plant , pyrolysis |

| Price: |

US $50000

/ SET

|

| Min. Order: | 1 SET |

| Last Online:24 Jan, 2018 |

Waste plastic pyrolysis plant

The recycling of waste plastics plant has increasingly become an important part of environmental protection. DoingGroup has developed a waste plastic pyrolysis plant in addition to plastic waste. The device can also handle waste solid waste organic waste such as waste tires / waste rubber / waste acrylic / garbage / medical waste / oil shale, the operation of the device is as follows:

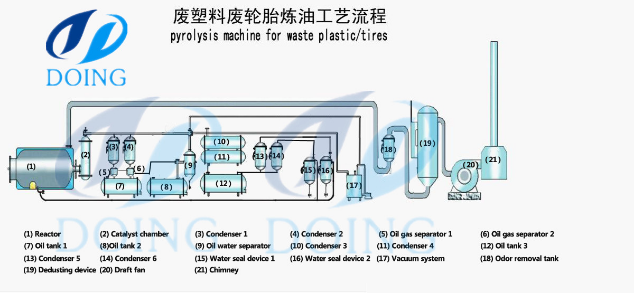

Plastic pyrolysis plant working process

1. The waste plastics and other organic solid waste by the conveyor belt to the bunker by the automatic feeding system to the cracking furnace, rotating the main furnace can control the positive and negative reversing switch control switch to adjust the organic raw materials in the main furnace of the material distribution, the total amount of material control in the total volume below two thirds, close the feed sealing door, and then open the heating system.

2. When the temperature reaches about 150 ℃, gas will be generated (most of the gas is the exhaust gas at this time). When the temperature reaches about 220 ℃, oil and gas will start to enter the multi-function separator. After the multi-function separator, there will be some oil separation down, the pipeline into the residual tank, the pump into the cracking furnace to continue heating cracking.

3. Oil and gas into the cooling system through the multi-function separator, the condensed oil and water flows into the oil-water separator through the pipe for oil-water separation measurement. Under the action of negative pressure, the non-condensable gas enters the micro-vacuum system through the cooling system piping and is filtered again.

4. The pyrolyzed flue gas enters the powerful atomization dedusting tower through the flue pipe to spray dust and cool down, and is discharged into the industrial exhaust gas purifier by the induced draft fan, finally reaching innocuous discharge.

This waste plastic pyrolysis plant proved to be successful due to some advantages of it:

1. Standard pressure vessel, Q245R standard boiler plate steel, the thickness of 16mm.

2. Seamless welding process, not easy to crack, long service life.

3.360 degree omnidirectional insulation cover, thermal insulation effect is more prominent.

4. A negative pressure, water seal device to ensure safe and efficient operation of equipment. And negative pressure equipment can increase the oil rate.

5. Environment friendly, energy efficient. Our equipment has a special dust deodorant device that can achieve the waste liquid waste disposal, will not cause any harm to the environment.

The main output of waste plastic pyrolysis plant for the cracker oil, carbon black, combustible gas.

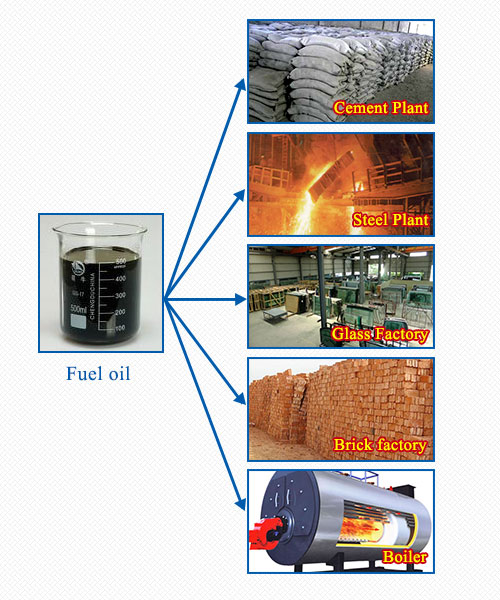

Fuel oil usage

Fuel Oil: Steel Plant, Boiler Heating, Heavy Oil Generator, Cement Plant. If it is further processed, will be refined oil, can be used for diesel generators, light fuel, heavy machinery.

Carbon black usage

Carbon black: Pressure ball combustion and refined toner, refined toner which can be used for new tires, rubber soles, pigment manufacturing.

Combustible gas: directly in the equipment was recycled for the reactor fuel heating, energy saving.

In order to meet the different needs of our customers, we have designed different capacities that we can choose according to our clients' needs and the capital budget. Any questions about our plastic pyrolysis plant, feel free to contact us.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.wastetireoil.com

http://www.china-doing.com