| Model: | DY 6T/8T/10T |

|---|---|

| Brand: | DY |

| Origin: | Made In China |

| Category: | Chemicals / Plastic Materials |

| Label: | tire pyrolysis plant , pyrolysis plant , pyrolysis |

| Price: |

US $50000

/ SET

|

| Min. Order: | 1 SET |

| Last Online:24 Jan, 2018 |

Used tire pyrolysis plant

In order to recycle waste tires, DoingGroup has developed a used tires pyrolysis plant for sale equipment. It can convert waste tires into pyrolysis oil, carbon black, steel wire and combustible gas by pyrolysis chemical reaction. It can not only achieve the purpose of protecting the environment but also benefit from it.

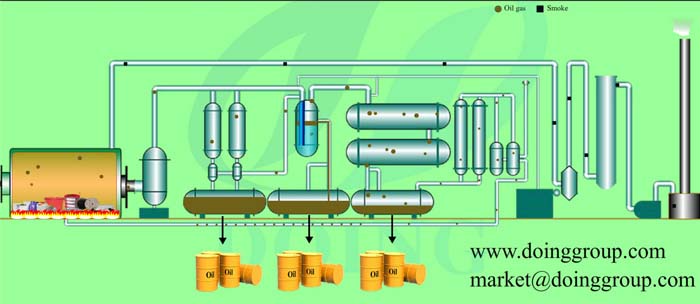

Waste tire pyrolysis plant working process

DoingGroup has adopted the most advanced cracking technology to turn waste tires into useful resources. The following is a brief description of the process of used tires pyrolysis plant

1. Use mechanical waste tires into the reactor, closing the entrance to prevent gas from flowing out.

2. Carbon, wood or fuel heating reactor, the reactor generally reach 200-300 degrees is the beginning of the cracking reaction, when the waste tires vaporized into oil vapor.

3. Oil and gas into the condensing system, liquefied into oil, was collected to the tank device. Our system has a negative pressure device, he can greatly improve the production of pyrolysis oil.

4. The liquefied petroleum gas that can not be liquefied under normal pressure will be returned to the reactor as fuel for combustion, which not only saves energy in environmental protection.

5. After completing the oil production, the reactor will be cooled. When the temperature drops to 40 degrees, the carbon black and wire will be removed automatically or manually.

Used tires pyrolysis plant welcomed in more and more countries because of his following advantages.

1. Turn waste into treasure

Plastic pyrolysis is the latest technology of DoingGroup. It can transform waste plastics into pyrolysis oil, carbon black and combustible gas through pyrolysis chemical reaction. These converted substances have a wide range of uses in our lives. At the same time, it is also very beneficial to our environmental protection because of the reprocessing of waste, reducing their environmental pollution.

2. High oil production rate

Our plastic pyrolysis can be used for 18 different raw materials, they will have a different amount of oil. Equipment with negative pressure device, it can not condensate oil vapor circulation filtration condensate system, so as to achieve the maximum amount of oil. After our many accurate measurements, the average oil yield of 60%.

3. Safe and environment friendly.

Our plastic pyrolysis for sale to provide buffer tank, vacuum device, water seal these safety devices to ensure that equipment is safe and efficient operation. And our plastic pyrolysis with oil-water separator and dust deodorization equipment, which can effectively deal with the waste gas generated during the operation of waste equipment.

These advantages make this device every day there will be nearly 10,000 RMB in revenue, and the market prospects are very broad. Through this used tires pyrolysis plant cracking reaction and condensation system, will produce a lot of fuel oil, carbon black, combustible gas. They are used in all walks of life.

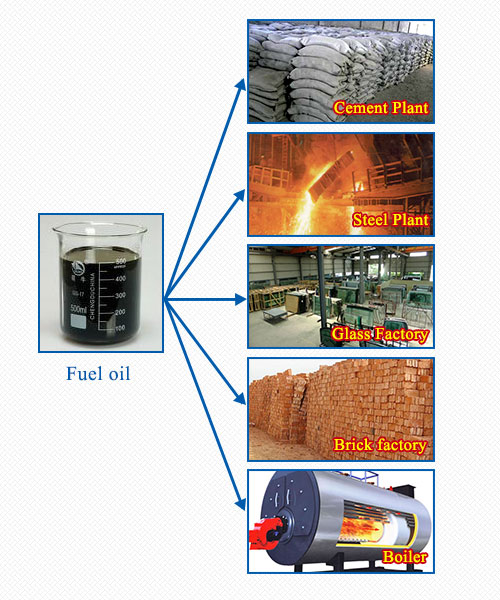

Fuel oil application

Fuel oil: steel plant. Boiler heating. Heavy oil power generation. Cement plants, but also further refined pyrolysis oil can also be used for diesel generators. Lightweight fuel. Heavy machinery

Carbon black application

Carbon black: pressure ball burning. Refined toner. Refined toner which can be used for new tires, rubber soles, paint manufacturing.

In order to meet the different needs of our customers, our processing capacity of used tires pyrolysis plant ranges from 3 to 12 tons, which is based on the customers' specific usage and fund budget of the equipment. If you are interested in the machine, we can customize according to your needs.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email: oilmachine@doinggroup.com

http://www.wastetireoil.com

http://www.china-doing.com