The rotary drill is driven by the power unit to rotate the rotary device of the drill, thus driving the drill pipe with the drill bit to rotate, and the drill bit is used to cut the soil. The rotary drilling rig is used for cast-in-place piles with mud retaining wall, and the drilling method is rotary drilling. According to different mud circulation modes, it can be divided into positive circulation rotary drilling rig and reverse circulation rotary drilling rig.

The rotary drilling rig is mainly composed of plane frame, belt drive wheel, gear box, winch, rotary drill disc, universal joint drive shaft, gantry frame, crown wheel, drill pipe and drill bit.

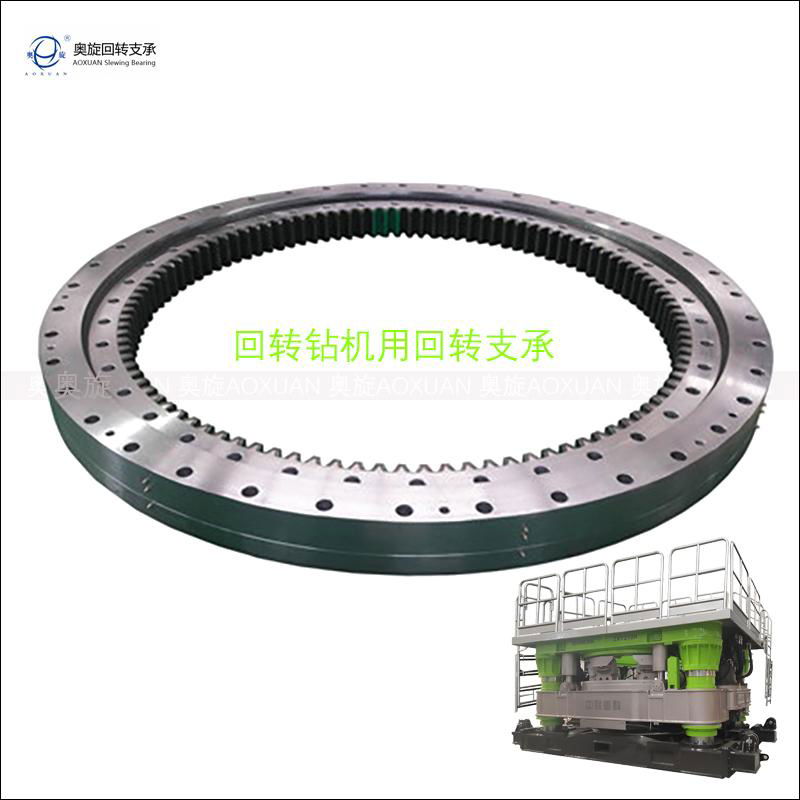

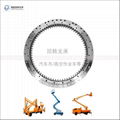

Slewing bearing can be used on rotary table bearings such as gear box and rotary drilling table. Slewing bearing is also known as rotary bearing and slewing bearing. Slewing bearing is widely used in real industry. It is known as "the joint of the machine". It is an important transmission element required by the machine that needs to make relative rotary motion between two objects, and also needs to bear axial force, radial force and overturning moment. Its main function is to support the rotating body of the machine, reduce the friction coefficient during its movement, and ensure its rotation accuracy.

Compared with general bearings, the rotating speed of slewing ring is lower.

Positive circulation rotary drilling is to use the rotary device of the drilling rig to drive the drilling tool to rotate and cut the rock and soil. At the same time, the mud pump is used to send mud (or clean water) to the drill pipe to wash the bottom of the hole. The washing fluid carrying rock cuttings rises along the annular space between the drill pipe and the hole wall, flows from the hole mouth to the sedimentation tank, and then is used after purification, and operates repeatedly, thus forming a positive circulation slag removal system; With the continuous discharge of drilling slag, the borehole continues to extend downward until it reaches the predetermined hole depth. Since this slag removal method is the same as that of geological exploration drilling, it is called positive circulation, which is different from the reverse circulation slag removal method that appeared later.

The reverse circulation rotary drilling rig hole forming is a hole forming method in which the drill pipe and drill bit are driven by the rotary device of the drilling rig to turn and cut the broken rock and soil, and the circulating wall protection mud is pumped by means of pumping, air lifting, spraying and other measures, and the drilling slag is sucked out of the hole from the inner cavity of the drill pipe. According to different pumping principles, it can be divided into three construction processes: pumping reverse circulation, air-lift reverse circulation and jet (jet) reverse circulation. Pumping reverse circulation is to directly use the suction function of sand pump to make the water flow in the drill pipe rise and form reverse circulation; Jet reverse circulation is to use the negative pressure generated by the high speed water flow from the jet pump to make the water flow in the drill pipe rise and form a reverse circulation; Air lift reverse circulation uses compressed air to circulate water. The rising speed of water flow in the drill pipe is related to the weight difference of liquid inside and outside the drill pipe, and the efficiency increases with the increase of hole depth. When the hole depth is less than 50m, pumping or jet reverse circulation should be selected; When the hole depth is greater than 50m, the gas-lift reverse circulation should be adopted.

Order process:

1. Consult customer service 2. Explain requirements 3. Confirm drawings 4. Sign contracts 5. Arrange production 6. Deliver goods from warehouse 7. Confirm receipt.

Under normal circumstances, the products are delivered in 3-7 days, and are now processed in 25-35 days, and customized products are delivered in about 45 days. Welcome to consult.