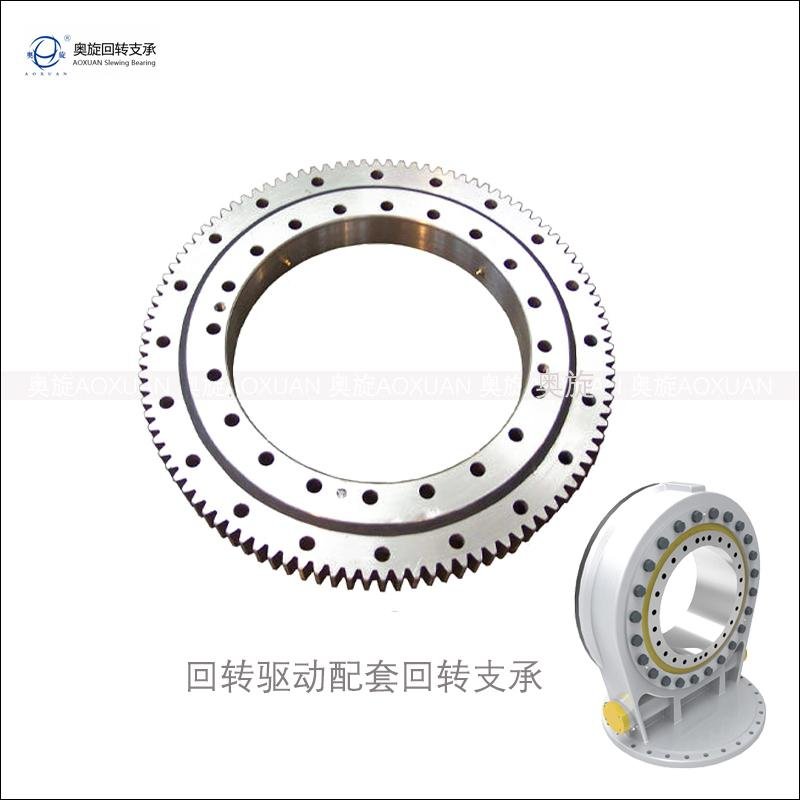

The slewing drive is a full-circle slewing reduction drive mechanism integrated with the driving power source. It uses the slewing bearing as the driving follower and the attachment of the mechanism. By attaching the driving part, the driving source and the cover to one of the inner and outer rings of the slewing bearing, the other ring is used as both the driving follower and the connecting base of the driven working parts. In this way, the slewing bearing itself is a full-circle slewing connector, The drive power source and main drive parts are efficiently configured to make it a universal reduction drive mechanism that integrates rotation, reduction and drive functions, but also has simple structure and convenient manufacturing and maintenance.

The slewing bearing is one of the important parts of the slewing drive, which can realize the function of displacement and act as a flexible displacement joint.

Slewing bearing is also known as rotary bearing and slewing bearing. Slewing bearing is widely used in real industry. It is known as "the joint of the machine". It is an important transmission element required by the machine that needs to make relative rotary motion between two objects, and also needs to bear axial force, radial force and overturning moment. Its main function is to support the rotating body of the machine, reduce the friction coefficient during its movement, and ensure its rotation accuracy.

Compared with general bearings, the rotating speed of slewing ring is lower. According to the different friction properties of moving elements, slewing bearings can be divided into rolling bearings and sliding bearings.

Product advantages:

1 Modularization: Due to the high integration of the rotary drive, users do not have to purchase and process each part of the rotary device one by one, which also reduces the preparation process at the beginning of product production to a certain extent, thus greatly improving labor productivity.

2 Safety: The worm gear and worm drive has the feature of reverse self-locking, which can realize reverse self-locking, that is, the worm gear can only be driven by the worm, but not by the worm gear. This feature enables slewing drive to be widely used in lifting, aerial work and other equipment. While improving the technological content of the main engine, it also greatly improves the operation stability and safety factor of the main engine. Compared with the traditional rotary products, the rotary drive has the advantages of simple installation, easy maintenance and saving installation space to a greater extent.

3 Simplify the design of the main engine: compared with the traditional gear drive, the worm gear and worm drive can obtain a relatively large reduction ratio. In some cases, it can save the reducer parts for the main engine, thus reducing the purchase cost for customers, and also greatly reducing the occurrence rate of the main engine failure.

Order process:

1. Consult customer service 2. Explain requirements 3. Confirm drawings 4. Sign contracts 5. Arrange production 6. Deliver goods from warehouse 7. Confirm receipt.

Under normal circumstances, the products are delivered in 3-7 days, and are now processed in 25-35 days, and customized products are delivered in about 45 days. Welcome to consult.