| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Metallic Powder |

| Label: | Titanium carbide , carbon target , sputtering targets |

| Price: |

¥150

/ pc

|

| Min. Order: | 1 pc |

Product Description

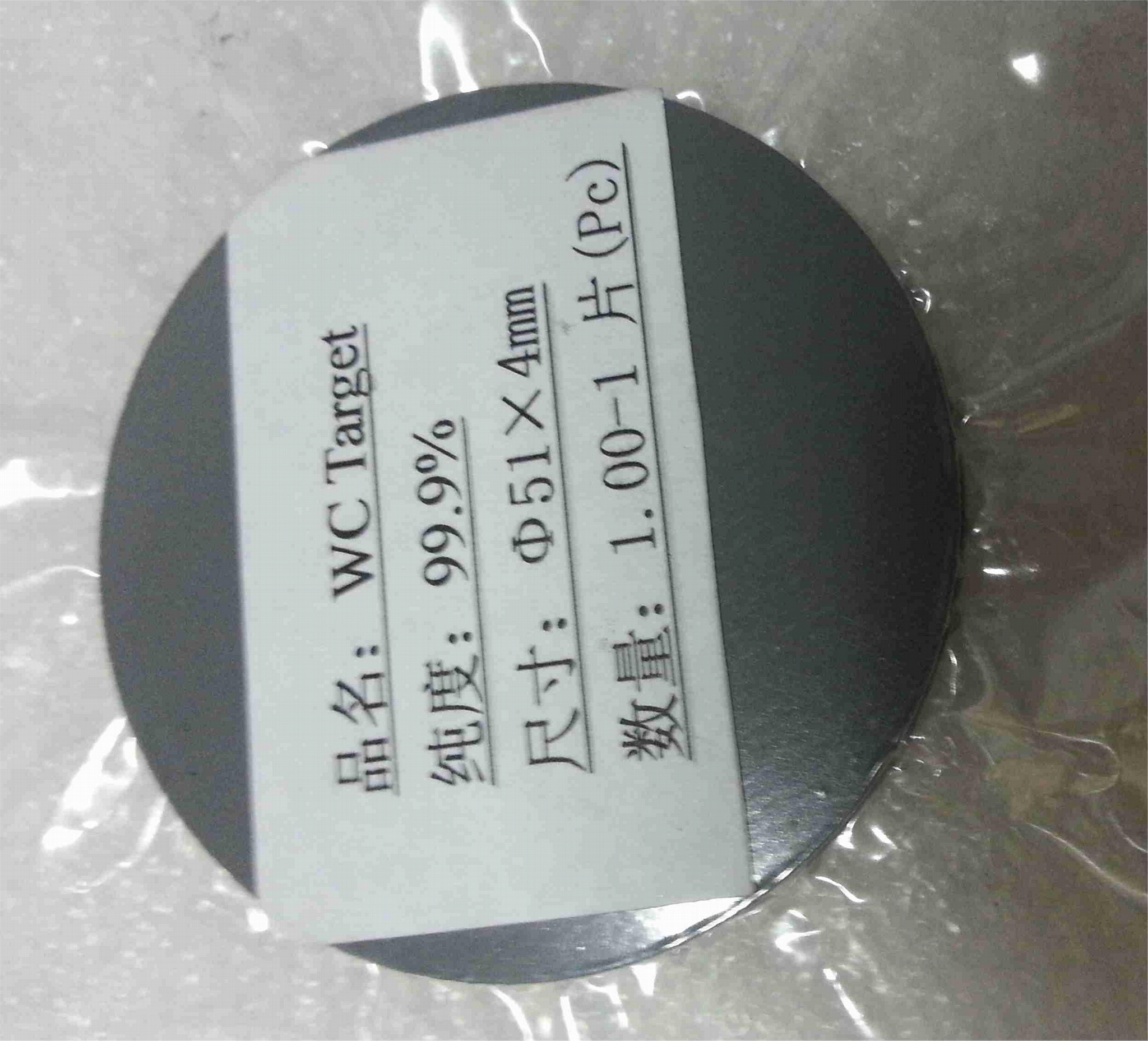

High-Purity Metal Carbon (C) Target Material for Magnetron Sputtering and Electron Beam Evaporation

Carbon (C) target material is a crucial component in sputtering technology. As a key material in sputtering processes, it plays a pivotal role in the microelectronics industry and hard coating applications due to its excellent electrical and thermal conductivity. This material not only provides a solid foundation for advancements in modern technology but also significantly enhances the performance of related industry products.

Our company specializes in the research, development, and production of high-quality materials, including single-element targets and electron beam evaporation particles. We offer the following materials:

SINGLE ELEMENTS

Aluminum (Al)

Nickel (Ni)

Antimony (Sb)

Niobium (Nb)

Arsenic (As)

Osmium (Os)

Barium (Ba)

Palladium (Pd)

Beryllium (Be)

Platinum (Pt)

Boron (B)

Rhenium (Re)

Cadmium (Cd)

Rhodium (Rh)

Carbon (C) [Featured]

Rubidium (Rb)

Chromium (Cr)

Ruthenium (Ru)

Cobalt (Co)

Selenium (Se)

Copper (Cu)

Silicon (Si)

Gallium (Ga)

Silver (Ag)

Germanium (Ge)

Tantalum (Ta)

Gold (Au)

Tellurium (Te)

Hafnium (Hf)

Tin (Sn)

Indium (In)

Titanium (Ti)

Iridium (Ir)

Tungsten (W)

Iron (Fe)

Vanadium (V)

Lead (Pb)

Yttrium (Y)

Magnesium (Mg)

Zinc (Zn)

Manganese (Mn)

Zirconium (Zr)

Molybdenum (Mo)

Material Characteristics:

Carbon target materials are renowned for their high purity, high density, and high melting point. High purity ensures minimal impurity content during preparation, guaranteeing the purity and uniformity of sputtered films, which is crucial for precision components in microelectronics. High density enhances sputtering efficiency and stability, ensuring uniform and efficient deposition on the substrate during coating processes. Additionally, the high melting point of carbon materials (e.g., graphite with a melting point of 3652ºC) allows the target to maintain stable physical and chemical properties in high-temperature environments, enabling high-temperature sputtering processes.

Industry Applications:

Microelectronics Industry: Carbon target materials exhibit significant advantages in microelectronics manufacturing. As integrated circuit technology continues to advance, the requirements for thin-film materials become increasingly stringent. Films prepared using carbon targets through sputtering technology not only possess exceptional hardness, effectively resisting physical wear and chemical erosion, but also significantly enhance the electrical properties of circuits, such as conductivity and signal transmission speed. Furthermore, their high thermal conductivity aids in rapid heat dissipation, protecting circuit components from high-temperature damage and improving the overall system's stability and reliability. Therefore, carbon target materials play an irreplaceable role in the manufacture of high-performance integrated circuits, microprocessors, and other critical electronic components.

Hard Coating Industry: Carbon target materials also demonstrate immense potential in the hard coating industry. Depositing a uniform carbon film on the surface of tools, molds, and other substrates through sputtering technology significantly enhances their surface hardness and wear resistance, extending their lifespan and reducing production costs. Especially in high-speed cutting and precision machining fields, coating tools prepared using carbon targets have become indispensable tools.

In summary, carbon target materials play a crucial role in the microelectronics industry and hard coating applications due to their superior electrical and thermal conductivity, as well as their high purity, high density, and high melting point characteristics. They not only improve the overall performance of products but also drive continuous progress and development in related industries. With the continuous advancement of technology and the expansion of application fields, the market prospects for carbon target materials will become even broader.

Additionally, we offer customized sizes and backplate bonding services to meet specific customer requirements, ensuring the best possible fit and performance for your application.

| Payment Terms: | TT |

|---|---|

Member Information

| Suzhou Zhongzhina Semiconductor Technology Co., Ltd. | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Manufacturer |

| Phone: | 95613164 |

| Contact: | spring (Jiangsu Province) |

| Last Online: | 17 Feb, 2025 |

Related Products of this Company

-

Zinc aluminum oxide target, zinc oxide

-

Indium Tin Oxide Target Magnetron

-

The translations for the given terms are

-

Osmium target, rhenium target, ruthenium

-

The translations for the given terms are

-

Copper Indium Selenide Target,

-

PVD Magnetron Sputtering Coating Target

-

The translations for the given terms are

-

The translations for the given terms are

-

Molybdenum-Niobium Target, Niobium Oxide